Performance Studies

The diversity of Composiflex customers and applications provides us with a broad portfolio of experience not common among other composite manufacturers. Our materials knowledge and production capabilities have become extremely valuable to aerospace and military engineers who seek to minimize weight by converting metal components to composite materials, commonly achieving a weight reduction of 30-40% or more. A variety of lightweight cores and inserts can be incorporated into the composite structure to increase rigidity, particularly important under bending loads Although “make-to-print” opportunities are always welcome, Composiflex engineers are accustomed to providing added customer value in several ways. In addition to standard analyses and tests, Composiflex can customize a performance study for your application.

Composiflex can either perform or manage a variety of analyses and physical tests to support your program.

Examples of Composiflex “extended value” Support:

- Corner and side impact studies to support man-portable applications.

- Project to assess impact energy absorption by various composite lay-ups.

- Composite material treatment studies to address EMI and antenna reflectivity performance.

- Material and product testing to embed antennas in composite structures.

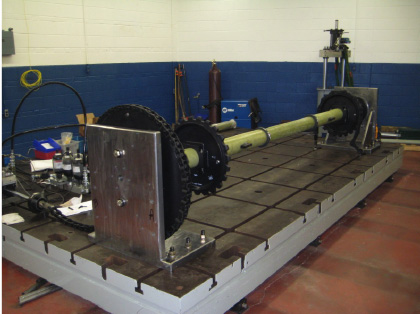

- High-torque testing of filament wound drive shaft systems.

- Application of 3-D printing / additive manufacturing technologies for products and tooling.