FlexPly Armor Products / Composite Ballistic

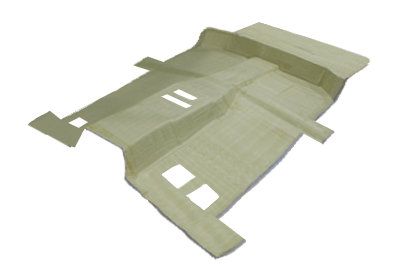

FlexPly Composite Armor offers a broad range of ballistic composite products for vehicles, aircraft, and personal protection. Solutions range from multi-piece kits for comprehensive protection of large ground or air vehicles to small individual components providing localized protection of personnel or equipment. For example, Composiflex offers SUV floor armor that defeats commonly specified hand grenade threats. Using the latest composite technologies and other materials like ceramic and steel, Composiflex provides solutions optimized for protection level, weight, cost, and availability of raw materials. Although standard NIJ and STANAG protection levels are supported, Composiflex also offers custom solutions tailored to each customer’s unique requirements.

Composiflex Support

To support armor customers, Composiflex offers:

- Proprietary FlexPLY™ materials and processing technique options

- MIL-SPEC materials and processing if required (including MIL-DTL-62474 PVB Phenolic)

- Design advice to meet requirements of defeat level, weight, and cost

- Tooling design and production

- Facilitation of third party testing

Composiflex’s FlexPLY™ products are often more flexible than other solutions. Utilized in SUV and other vehicular applications, our FlexPLY™ products are much easier to install. Composiflex also provides MIL-DTL-62472 / MIL-PRF-62474-C and other industry standard options.

The applications that Composiflex supports include:

- SUV and other ground vehicle armor

- Aircraft armor

- Blast protection

- Ballistic shields

- Portable armor